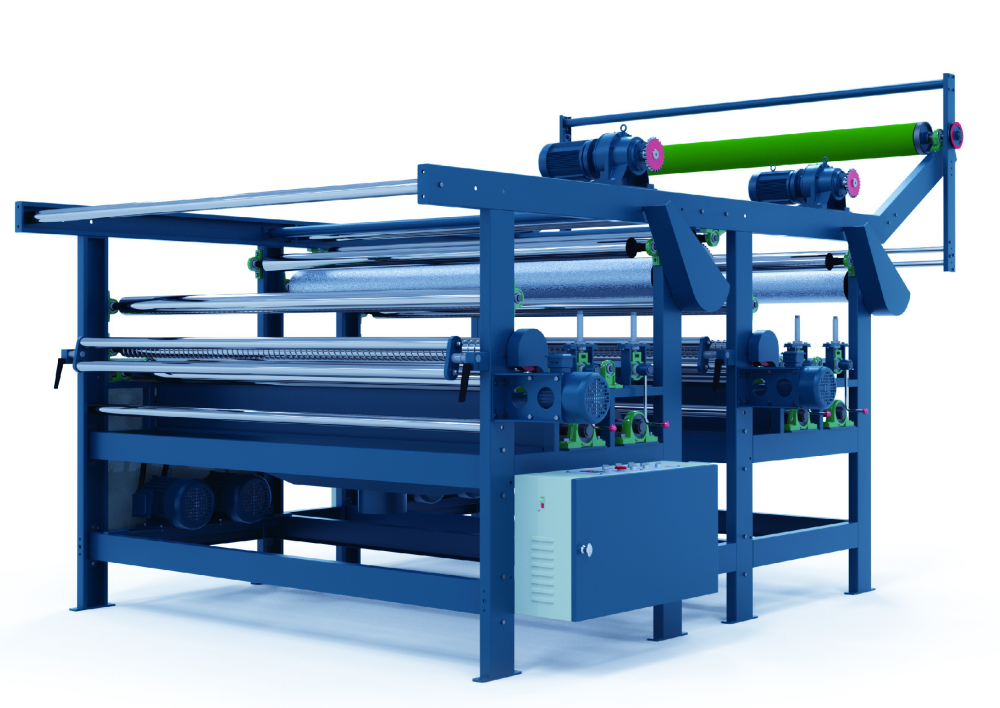

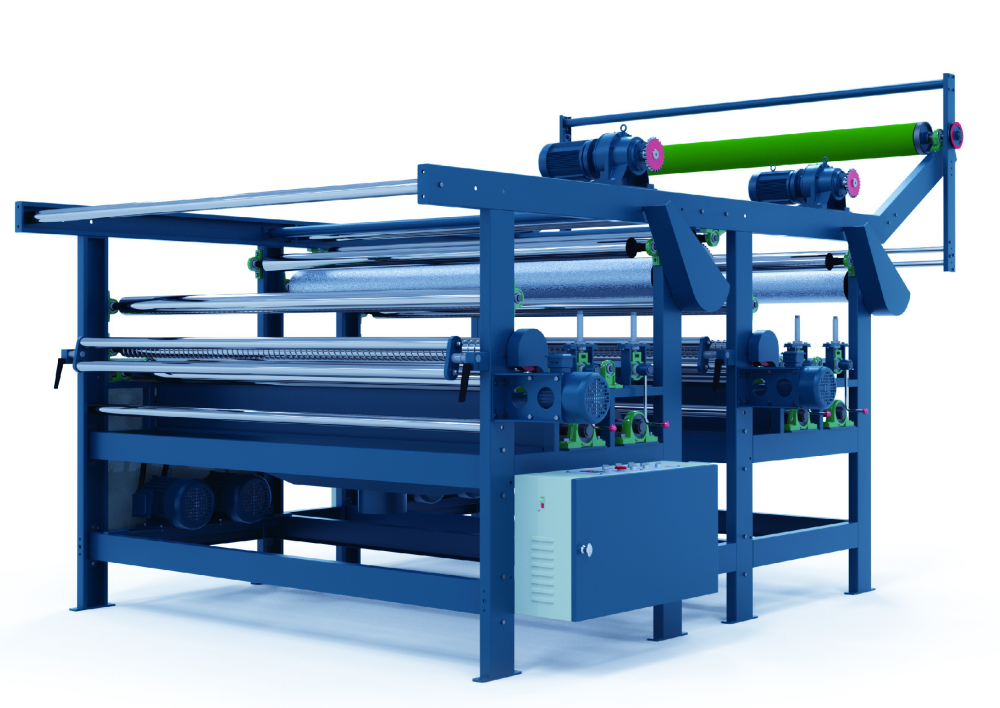

1 Application:

This machine is suitable for surface raising of knitting fabrics, blanket, woolen, fur and carpet.

2 Structure :

This machine is made of frame, brushing parts and guiding parts.

2.1 Frame structure: Machine frame is welded by hot rolling 14a U-steel,the structure is strong and easy for assembling and disassembling.

2.2 Brushing parts: Two ends of brushing roller are supported by bearing seat and fixed on the frame,

driven by 3 phases motor, adjust the distance between fabric guiding seat and brushing roller by screw.

2.3 Guiding parts: made of planet-cycloid retarder, pull roller, fabric guiding roller and swing frame.

3 Main data:

Nominal width

|

2500 (mm)

|

Production capacity

|

15mm/min (variable)

|

Brushing roller rotating speed

|

1000 fore /1100 rear

|

Diameter of rushing roller

|

Ф156

|

Number of rushing roller

|

4pcs

|

Motor power

|

25kw(not include dust exhaustor)

|

Spreading roller power

|

3kw (opt. parts)

|

Working voltage

|

380V

|

Brushing roller bearing temperature rise

|

≤30℃

|

Noise level

|

≤80db(A)

|

Overall dimensions(L×W×H)

|

4650×3700×3060

|

Machine weight

|

2T

|

|