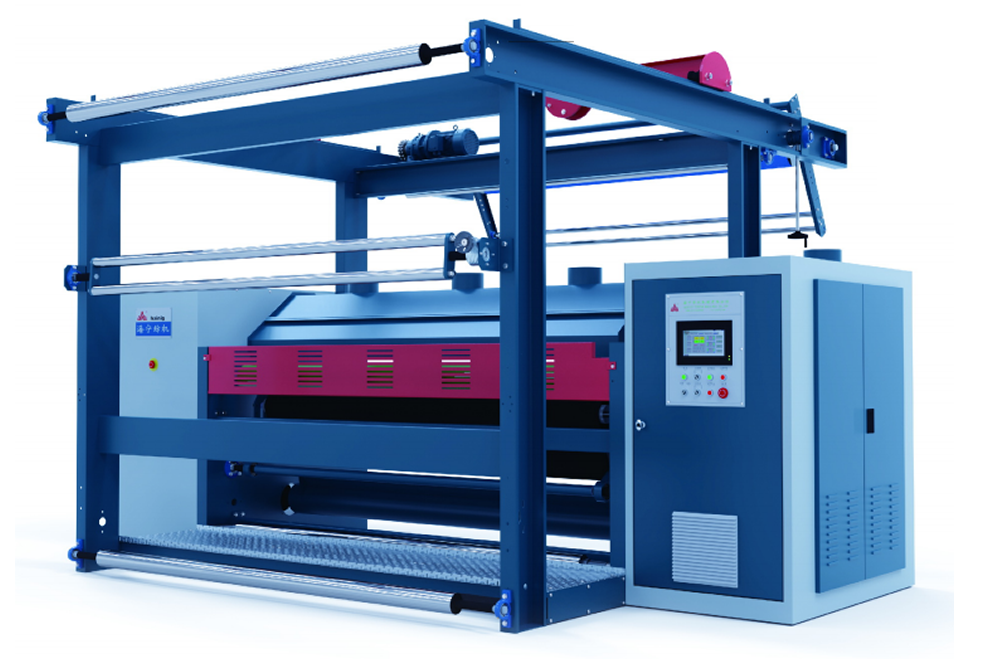

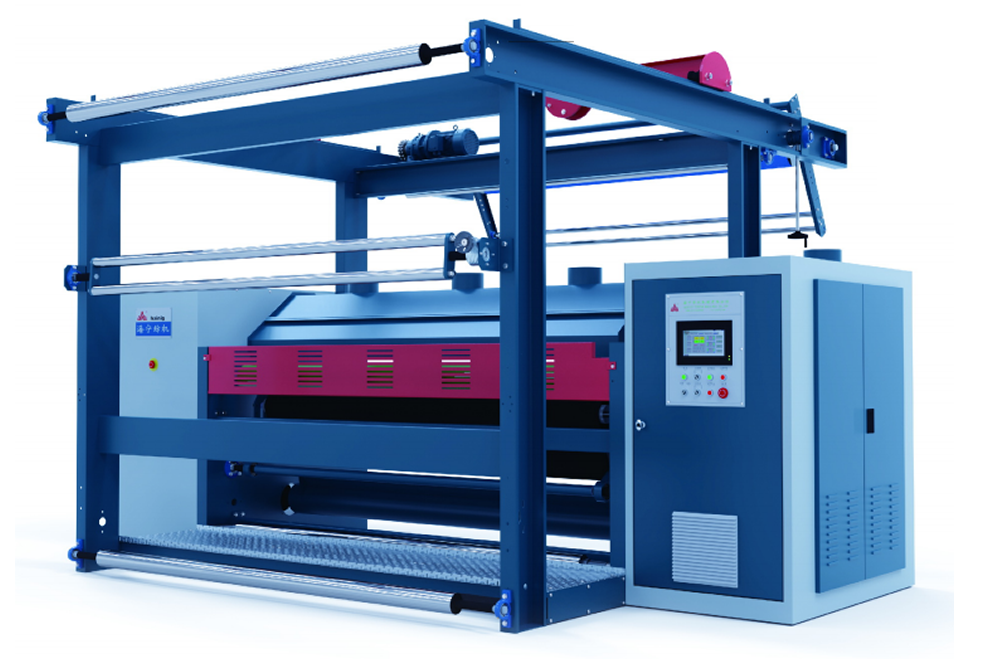

This machine is applicable to the polishing treatment of various natural and chemical fiber woven fabrics, knitted fabrics and tufted fabrics. It is mainly used for the polishing treatment of smooth wool overcoats, cashmere overcoats and blankets, and also for the ironing treatment of velvet, velvet, plush or artificial fur. After the polishing treatment, the surface of the fabric is fluffy and soft, and the hair is straight and bright, which is comparable to natural fabrics. Its working efficiency can be improved step by step according to the diameter of the polishing roller of the calender.

1. The modular design of the same platform is adopted. Type E adopts conventional electric heating and type G adopts natural gas heating, φ 320, φ 370、 φ 415 and other mirror ironing rollers with different diameters can be selected to obtain different ironing styles; Natural gas heating and conventional electric heating are optional to meet customer needs.

2. PLC+touch screen control, temperature control module temperature control, control temperature more accurately. The feed motor and the discharge motor are regulated by frequency converter. The tension of each section can be adjusted respectively. The cloth speed can be arbitrarily selected within 10-40 meters/minute. The value is directly displayed on the touch screen. The tension between each group of guide rollers is adjustable.

3. Before polishing, there is a set of double expanding rollers. Different threading methods can achieve the effect of expanding the front, reverse and both sides, with wide applicability. |